螺丝攻对照表

2025-01-23

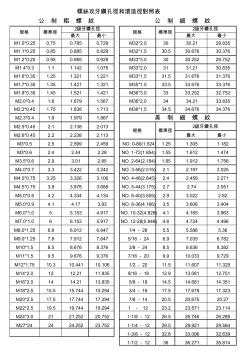

最大 最小 最大 最小 G4-G6 G7-G8 G9 G4-G6 G7-G8 G9 硬材 软材 M1.0*0.25 0.75 0.785 0.729 M12*1.0 11.00 11.153 10.917 M1.0*0.25 0.86 0.88 - No 2 - 56UNC 1.94 - - W1/8 - 40 2.65 2.60 M1.1*0.25 0.85 0.885 0.829 M12*0.5 11.50 11.520 11.400 M1.1*0.25 0.96 0.98 - No 3 - 48 2.23 - - W5/32 - 32 3.25 3.20 M1.2*0.25 0.95 0.985 0.929 M14*1.5 12.50 12.676 12.376 M1.2*0.25 1.06 1.08 - No 4 - 40 2.50 - - W3/16 - 24 3.

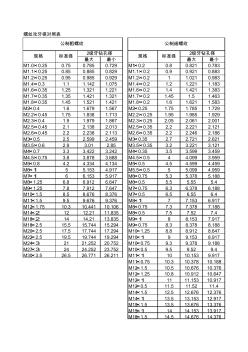

最大最小最大最小 m1.0×0.250.750.7850.729m1.0×0.20.800.8210.783 m1.1×0.250.850.8850.829m1.1×0.20.900.9210.883 m1.2×0.250.950.9850.929m1.2×0.21.001.0210.983 m1.4×0.31.101.1421.075m1.4×0.21.201.2211.183 m1.6×0.351.251.3211.221m1.6×0.21.401.4211.383 m1.7×0.351.351.4211.321m1.7×0.21.501.5211.483 m1.8×0.351.451.5211.421m1.8×0.21.601.6211.583 m2.0×0.41.601.67

最大最小最大最小g4-g6g7-g8g9g4-g6g7-g8硬材软材 m1.0*0.250.750.7850.729m12*1.011.0011.15310.917m1.0*0.250.860.88no.2-56unc1.942.652.60 m1.1*0.250.850.8850.829m12*0.511.5011.52011.400m1.1*0.250.960.98no.3-482.233.253.20 m1.2*0.250.950.9850.929m14*1.512.5012.67612.376m1.2*0.251.061.08no.4-402.503.753.70 m1.4*0.31.101.1421.075m14*1.013.0013.15312.917

编辑推荐下载

3 螺丝攻牙钻孔径和滚丝径对照表 公制细螺纹美制细螺纹 规格标准径 2级牙钻孔径 规格(unc)标准径 2级牙钻孔径 最大最小最大最小 m1.0×0.20.800.8210.783no.0-80(1.524)1.251.3051.182 m1.1×0.20.900.9210.883no.1-72(1.854)1.551.6121.474 m1.2×0.21.001.0210.983no.2-64(2.184)1.851.9121.756 m1.4×0.21.201.2211.183no.3-56(2.515)2.102.1972.025 m1.6×0.21.401.4211.383no.4-48(2.845)2.402.4582.271 m1.7×0.21.451.5001.460n

1/10 微锥自锁密封螺纹技术简介 锥螺纹具有良好的自锁密封和耐高温性能,但传统的锥螺纹生产 是极其困难的,成本也高出普通螺纹好几倍。 现介绍一种微锥自锁密封螺纹的技术,它的生产成本与生产普通 螺纹是一样的,生产的工艺与装备也与传统的相同,也就是说,用现 时生产普通螺纹的设备,就能生产出这种具有抗高温、抗振,并具有 自锁密封性能的螺纹。 1.传统的锥螺纹生产困难、生产成本高的原因 原因在于该锥螺纹的大头尺寸与小头尺寸,是两个不同的公称尺 寸数值,如大头直径是12mm,小头尺寸是10mm。 这种改变了公称尺寸的螺纹,要进行机加工是很困难的,精度也 不易保证,由于工艺手段的不足,就造成生产成本高的问题。 2.如何用最简单的办法实现锥螺纹的自锁、密封性能 要实现锥螺纹的抗高温、自锁、密封性能,其实并不需要这般“劳 师动众”,仅运用我们“公差与配合”的知识与

热门文档 螺丝攻对照表

上限下限上限 m1.0×0.250.750.7850.729m1.0×0.200.80.821 m1.1×0.250.850.8850.829m1.1×0.200.90.921 m1.2×0.250.950.9850.929m1.2×0.2011.021 m1.4×0.251.11.1421.075m1.4×0.201.21.221 m1.6×0.251.251.3211.221m1.6×0.201.41.421 m1.7×0.451.351.4211.321m1.8×0.21.61.621 m1.8×0.451.451.5211.421m2.0×0.251.751.785 m2×0.51.61.6791.567m2.5×0.352.22.221 m2.2×0.61.751.8

最大最小最大最小硬材软材 m1.0×0.250.750.7850.729m12×1.011.0011.15310.9171-64uncg51.761.68m1.0×0.25g40.920.892.652.60 m1.1×0.250.850.8850.829m12×0.511.5011.52011.4002-56g42.041.96m1.2×0.25g41.111.093.253.20 m1.2×0.250.950.9850.929m14×1.512.5012.67612.3763-48g42.352.25m1.4×0.30g41.301.263.753.70 m1.4×0.31.101.1421.075m14×1.013.00

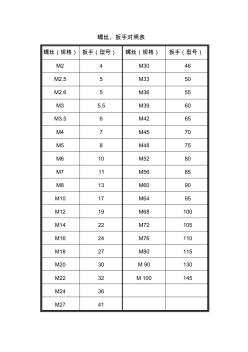

螺丝、扳手对照表 螺丝(规格)扳手(型号)螺丝(规格)扳手(型号) m24m3046 m2.55m3350 m2.65m3655 m35.5m3960 m3.56m4265 m47m4570 m58m4875 m610m5280 m711m5685 m813m6090 m1017m6495 m1219m68100 m1422m72105 m1624m76110 m1827m80115 m2030m90130 m2232m100145 m2436 m2741

最大最小最大最小 m1.0*0.250.750.7850.729m32*2.03030.2129.835 m1.1*0.250.850.8850.829m32*1.530.530.67630.376 m1.2*0.250.950.9850.929m33*3.03030.25229.752 m1.4*0.31.11.1421.075m33*2.03131.2130.835 m1.6*0.351.251.3211.221m33*1.531.531.67631.376 m1.7*0.351.351.4211.321m35*1.533.533.67633.376 m1.8*0.351.451.5211.421m36*3.03333.25232.752 m2.0*0.41.61.6791.5

螺丝攻牙径对照表 最大最小最大最小 m1.0×0.250.750.7850.729m1×0.20.80.8210.783 m1.1×0.250.850.8850.829m1.1×0.20.90.9210.883 m1.2×0.250.950.9850.929m1.2×0.211.0210.983 m1.4×0.31.11.1421.075m1.4×0.21.21.2211.183 m1.6×0.351.251.3211.221m1.6×0.21.41.4211.383 m1.7×0.351.351.4211.321m1.7×0.21.451.51.463 m1.8×0.351.451.5211.421m1.8×0.21.61.6211.583 m2×0.41.61.6791.567

精华文档 螺丝攻对照表

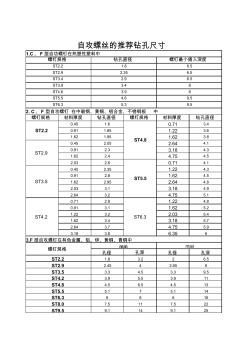

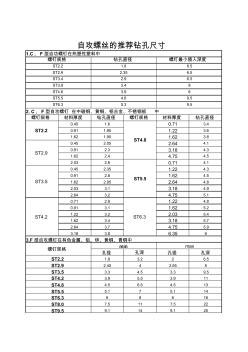

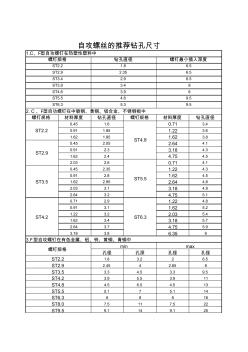

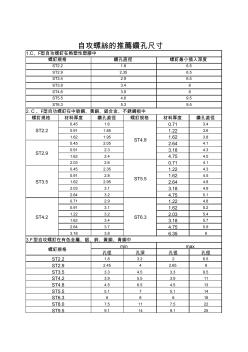

螺钉规格材料厚度钻孔直径螺钉规格材料厚度钻孔直径 0.451.60.713.4 0.911.851.223.6 1.621.951.623.8 0.452.052.644.1 0.912.33.184.3 1.622.44.754.5 2.032.60.714.1 0.452.351.224.3 0.912.81.624.5 1.622.952.644.8 2.033.13.184.9 2.643.24.755.1 0.712.91.224.8 0.913.11.625.2 1.223.22.035.4 1.623.43.185.7 2.643.74.755.9 3.183.86.356 孔径孔深孔径孔深 1.83.226.5 2.4542.658 3.3

螺钉规格材料厚度钻孔直径螺钉规格材料厚度钻孔直径 0.451.60.713.4 0.911.851.223.6 1.621.951.623.8 0.452.052.644.1 0.912.33.184.3 1.622.44.754.5 2.032.60.714.1 0.452.351.224.3 0.912.81.624.5 1.622.952.644.8 2.033.13.184.9 2.643.24.755.1 0.712.91.224.8 0.913.11.625.2 1.223.22.035.4 1.623.43.185.7 2.643.74.755.9 3.183.86.356 孔径孔深孔径孔深 1.83.226.5 2.4542.658 3.3

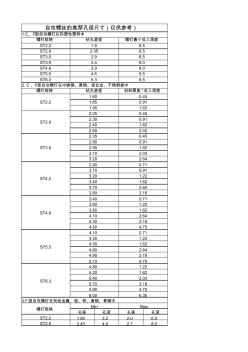

孔径孔深孔径孔深 1.803.22.06.5 2.454.02.78.0 自攻螺丝的推荐孔径尺寸(仅供参考) 钻孔直径 1.8 2.35 2.9 3.4 3.9 4.6 5.3 st2.9 st3.5 st3.9 st4.6 st5.5 6.5 螺钉最小攻入深度 6.5 6.5 螺钉规格 st2.2 8.0 8.0 9.5 9.5 2.c、f型自功螺钉在中碳钢、黄铜、铝合金、不锈钢板中 st6.3 st5.5 st4.8 st4.2 st3.5 st6.3 0.91 1.22 1.62 2.64 材料厚度/攻入深度钻孔直径 st2.9 st2.2 螺钉规格 0.45 0.91 1.62 0.45 0.91 1.62 2.03 1.62 1.60 1.85 1.95 2.05 2.30 2.40 2.60 2.35 2.80 3.18 0.71 1.22 5.70 5.

螺钉规格材料厚度钻孔直径螺钉规格材料厚度钻孔直径 0.451.60.713.4 0.911.851.223.6 1.621.951.623.8 0.452.052.644.1 0.912.33.184.3 1.622.44.754.5 2.032.60.714.1 0.452.351.224.3 0.912.81.624.5 1.622.952.644.8 2.033.13.184.9 2.643.24.755.1 0.712.91.224.8 0.913.11.625.2 1.223.22.035.4 1.623.43.185.7 2.643.74.755.9 3.183.86.356 孔径孔深孔径孔径 1.83.226.5 2.4542.658 3.3

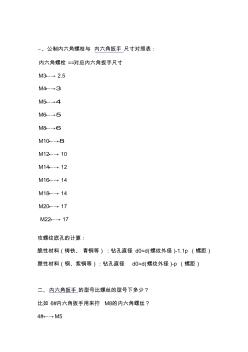

一、公制内六角螺栓与内六角扳手尺寸对照表: 内六角螺栓==对应内六角扳手尺寸 m3←→2.5 m4←→3 m5←→4 m6←→5 m8←→6 m10←→8 m12←→10 m14←→12 m16←→14 m18←→14 m20←→17 m22←→17 攻螺纹底孔的计算: 脆性材料(铸铁、青铜等):钻孔直径d0=d(螺纹外径)-1.1p(螺距) 塑性材料(钢、紫铜等):钻孔直径d0=d(螺纹外径)-p(螺距) 二、内六角扳手的型号比螺丝的型号下多少? 比如6#内六角扳手用来拧m8的内六角螺丝? 4#←→m5 5#←→m6 6#←→m8 8#←→m10 10#←→m12 12#←→m14,m16 14#←→m16,m20 17#←→m20 19#←→m24 22#,←→m30 27#←→m36 三、外六角所用的开口扳手以六角螺母对应比

最新文档 螺丝攻对照表

一、公制内六角螺栓与尺寸对照表: 内六角螺栓==对应内六角扳手尺寸 m3←→2.5 m4←→3 m5←→4 m6←→5 m8←→6 m10←→8 m12←→10 m14←→12 m16←→14 m18←→14 m20←→17 m22←→17 攻螺纹底孔的计算: 脆性材料(铸铁、青铜等):钻孔直径d0=d(螺纹外径)-1.1p(螺距) 塑性材料(钢、紫铜等):钻孔直径d0=d(螺纹外径)-p(螺距) 二、的型号比螺丝的型号下多少? 比如6#内六角扳手用来拧m8的内六角螺丝? 4#←→m5 5#←→m6 6#←→m8 8#←→m10 10#←→m12 12#←→m14,m16 14#←→m16,m20 17#←→m20 19#←→m24 22#,←→m30 27#←→m36 三、外六角所用的开口扳手以六角螺母对应比较准确,因为存在六角 头螺栓和小六角头螺栓。 常用的开口扳

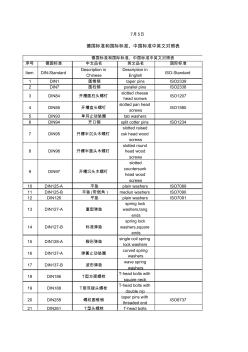

序号德国标准中文品名英文品名国际标准 itemdin-standard descriptionin chinese descriptionin englishiso-standard 1din1圆锥销taperpinsiso2339 2din7圆柱销parallelpinsiso2338 3din84开槽圆柱头螺钉 slottedcheese headscrewsiso1207 4din85开槽盘头螺钉 slottedpanhead screwsiso1580 5din93单耳止动垫圈tabwashers 6din94开口销splitcotterpinsiso1234 7din95开槽半沉头木螺钉 slottedraised cskheadwood screws 8din96开槽半圆头木螺钉 slot

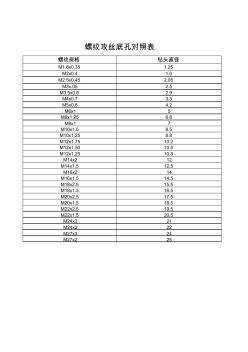

螺纹规格钻头直径 m1.6x0.351.25 m2x0.41.6 m2.5x0.452.05 m3x.052.5 m3.5x0.62.9 m4x0.73.3 m5x0.84.2 m6x15 m8x1.256.8 m8x17 m10x1.58.5 m10x1.258.8 m12x1.7510.2 m12x1.5010.5 m12x1.2510.8 m14x212 m14x1.512.5 m16x214 m16x1.514.5 m18x2.515.5 m18x1.516.5 m20x2.517.5 m20x1.518.5 m22x2.519.5 m22x1.520.5 m24x321 m24x222 m27x324 m27x225 螺纹攻丝底孔对照表

自攻螺钉 ?六角头自钻自攻螺钉hexagonwasherheaddrilling screwswithtappingscrewthread dineniso15480|代替din7504 ?六角凸缘头自钻自攻螺钉hexagonwasherheaddrilling screwswithtappingscrewsthread dineniso15480 ?十字槽盘头自钻自攻螺钉crossrecessedpanhead drillingscrewswithtappingscrewthread dineniso15481 ?十字槽盘头自钻自攻螺钉crossrecessedpanhead drllingscrewswithtappingscrewthread di

一、公制内六角螺栓与内六角扳手尺寸对照表: 内六角螺栓==对应内六角扳手尺寸 m3←→2.5 m4←→3 m5←→4 m6←→5 m8←→6 m10←→8 m12←→10 m14←→12 m16←→14 m18←→14 m20←→17 m22←→17 攻螺纹底孔的计算: 脆性材料(铸铁、青铜等):钻孔直径d0=d(螺纹外径)-1.1p(螺距) 塑性材料(钢、紫铜等):钻孔直径d0=d(螺纹外径)-p(螺距) 二、内六角扳手的型号比螺丝的型号下多少? 比如6#内六角扳手用来拧m8的内六角螺丝? 4#←→m5 5#←→m6 6#←→m8 8#←→m10 10#←→m12 12#←→m14,m16 14#←→m16,m20 17#←→m20 19#←→m24 22#,←→m30 27#←→m36 三、外六角所用的开口扳手以六角螺母对应比较准确,因为存在六

螺釘規格材料厚度鑽孔直徑螺釘規格材料厚度鑽孔直徑 0.451.60.713.4 0.911.851.223.6 1.621.951.623.8 0.452.052.644.1 0.912.33.184.3 1.622.44.754.5 2.032.60.714.1 0.452.351.224.3 0.912.81.624.5 1.622.952.644.8 2.033.13.184.9 2.643.24.755.1 0.712.91.224.8 0.913.11.625.2 1.223.22.035.4 1.623.43.185.7 2.643.74.755.9 3.183.86.356 孔徑孔深孔徑孔徑 1.83.226.5 2.4542.658 3.3

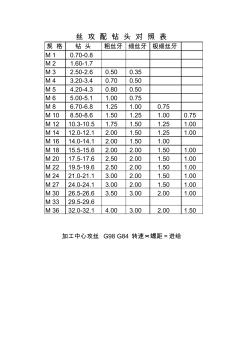

规格钻头粗丝牙细丝牙极细丝牙 m10.70-0.8 m21.60-1.7 m32.50-2.60.500.35 m43.20-3.40.700.50 m54.20-4.30.800.50 m65.00-5.11.000.75 m86.70-6.81.251.000.75 m108.50-8.61.501.251.000.75 m1210.3-10.51.751.501.251.00 m1412.0-12.12.001.501.251.00 m1614.0-14.12.001.501.00 m1815.5-15.62.002.001.501.00 m2017.5-17.62.502.001.501.00 m2219.5-19.62.502.001.50

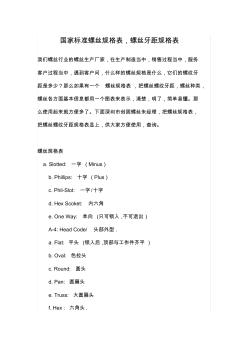

国家标准螺丝规格表,螺丝牙距规格表 我们螺丝行业的螺丝生产厂家,在生产制造当中,销售过程当中,服务 客户过程当中,遇到客户问,什么样的螺丝规格是什么,它们的螺纹牙 距是多少?那么如果有一个螺丝规格表,把螺丝螺纹牙距,螺丝种类, 螺丝各方面基本信息都用一个图表来表示,清楚,明了,简单易懂。那 么使用起来就方便多了。下面深圳市创固螺丝朱经理,把螺丝规格表, 把螺丝螺纹牙距规格表显上,供大家方便使用,查询。 螺丝规格表 a.slotted:一字(minus) b.phillips:十字(plus) c.phil-slot:一字/十字 d.hexscoket:内六角 e.oneway:单向(只可锁入,不可退出) a-4:headcode/头部外型. a.flat:平头(锁入后,顶部与工作件齐平) b.oval:色拉头 c.ro

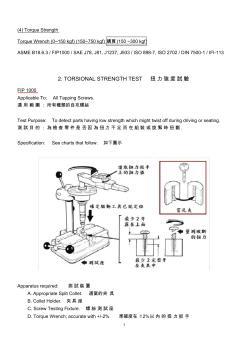

1 (4)torquestrength torquewrench(0~150kgf)(150~750kgf)購買(150~300kgf) asmeb18.6.3/fip1000/saej78,j81,j1237,j933/iso898-7,iso2702/din7500-1/ifi-113 2.torsionalstrengthtest扭力強度試驗 fip1000 applicableto:alltappingscrews. 適用範圍:所有種類的自攻螺絲 testpurpose:todetectpartshavinglowstrengthwhichmighttwistoffduringdrivingorseating. 測試目的:為檢查零件是否因為扭力不足而在組裝或

1 (4)torquestrength torquewrench(0~150kgf)(150~750kgf)購買(150~300kgf) asmeb18.6.3/fip1000/saej78,j81,j1237,j933/iso898-7,iso2702/din7500-1/ifi-113 2.torsionalstrengthtest扭力強度試驗 fip1000 applicableto:alltappingscrews. 適用範圍:所有種類的自攻螺絲 testpurpose:todetectpartshavinglowstrengthwhichmighttwistoffduringdrivingorseating. 測試目的:為檢查零件是否因為扭力不足而在組裝或

文辑创建者

我要分享 >

职位:消防工程师

擅长专业:土建 安装 装饰 市政 园林

相关编辑

文辑推荐

知识推荐

百科推荐