桥架吊杆计算

2025-04-07

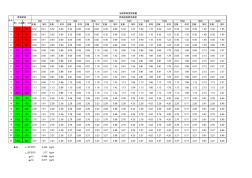

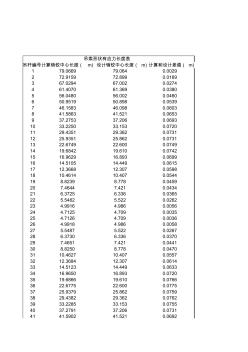

角铁 角钢长度 吊架间隔 每米长度 kg/m kg/桥架 米 桥架( 50*50) L30*3 0.1 1.5 0.0667 1.373 0.091533 桥架( 100*50) L30*3 0.2 1.5 0.1333 1.373 0.183067 桥架( 150*75) L30*3 0.25 1.5 0.1667 1.373 0.228833 桥架( 200*100) L30*3 0.3 1.5 0.2000 1.373 0.2746 桥架( 300*100) L40*4 0.4 1.5 0.2667 2.373 0.6328 桥架( 400*200) L40*4 0.5 1.5 0.3333 2.422 0.807333 桥架( 500*200) L40*4 0.6 1.5 0.4000 3.422 1.3688 桥架( 600*200) L50*5 0.7 1.5 0.4667 3

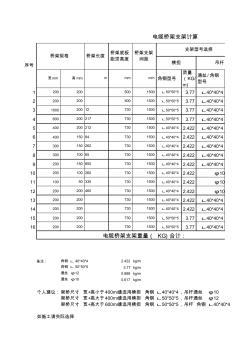

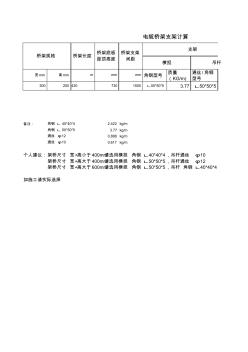

宽mm高mmmmmmm角钢型号 质量 (kg/ m) 通丝/角钢 型号 12002005001500∟50*50*53.77∟40*40*4 22002005001500∟50*50*53.77∟40*40*4 31000200127301500∟50*50*53.77∟40*40*4 46002002177301500∟50*50*53.77∟40*40*4 54002002127301500∟40*40*42.422∟40*40*4 6400150847301500∟40*40*42.422∟40*40*4 73001502627301500∟40*40*42.422∟40*40*4 8300100657301500∟40*40*42.422∟40*

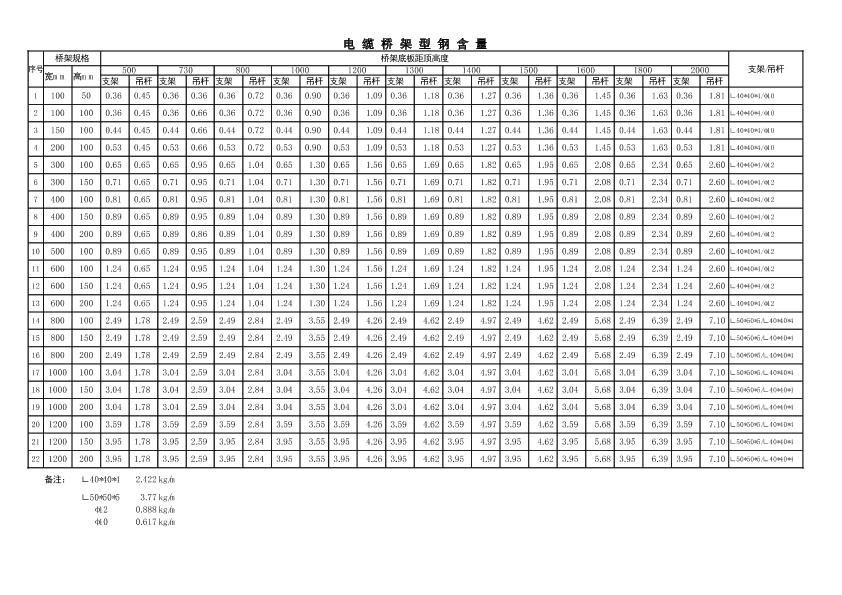

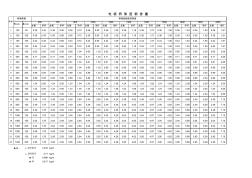

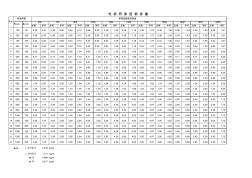

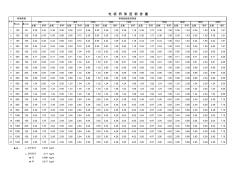

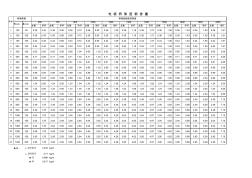

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

编辑推荐下载

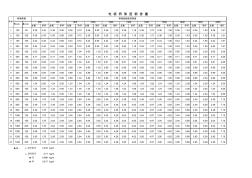

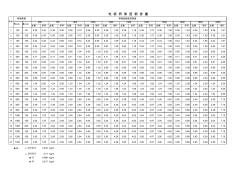

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

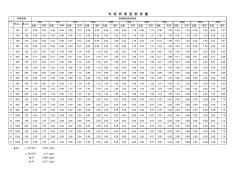

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.320.410.320.600.320.660.320.820.320.990.321.070.321.150.321.230.321.320.321.480.321.65 21001000.320.410.320.600.320.660.320.820.320.990.321.070.321.150.321.230.321.320.321.480.321.65 31501000.400.410.400.600.400.660.400.820.400.990.401.070.401.150.401.230.40

热门文档 桥架吊杆计算

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

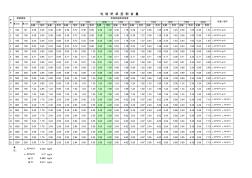

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81∟40*40*4/φ10 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81∟40*40*4/φ10 31501000.440.450.440.660.440.720.440.900.441.090.441.

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

精华文档 桥架吊杆计算

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.320.410.320.600.320.660.320.820.320.990.321.070.321.150.321.230.321.320.321.480.321.65∟40*40*4/φ10 21001000.320.410.320.600.320.660.320.820.320.990.321.070.321.150.321.230.321.320.321.480.321.65∟40*40*4/φ10 31501000.400.410.400.600.400.660.400.820.400.990.401.

宽mm高mmmmmmm角钢型号 质量 (kg/m) 通丝/角钢 型号 3002004307301500∟50*50*53.77∟50*50*5 备注:2.422kg/m 3.77kg/m 0.888kg/m 0.617kg/m 个人建议:架桥尺寸宽+高小于400mm请选用横担角钢∟40*40*4,吊杆通丝φ10 架桥尺寸宽+高大于400mm请选用横担角钢∟50*50*5,吊杆通丝φ12 架桥尺寸宽+高大于600mm请选用横担角钢∟50*50*5,吊杆角钢∟40*40*4 如施工请实际选择 通丝φ12 通丝φ10 桥架长度 桥架底板 距顶高度 桥架支架 间距 桥架规格 电缆桥架支架计算 支架 横担吊杆 角钢∟40*40*4 角钢∟50*50*5 质量 (kg/m)%kgkgkg 3.

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆支架吊杆 1100500.360.450.360.360.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 21001000.360.450.360.660.360.720.360.900.361.090.361.180.361.270.361.360.361.450.361.630.361.81 31501000.440.450.440.660.440.720.440.900.441.090.441.180.441.270.441.360.44

注:在下表中输入桥架规格、桥架长度、吊杆长度 规格理论重量 kg/m 长度m规格理论重量 kg/m 长度m间距m个数重量100kg 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.000000.00 001.00

最新文档 桥架吊杆计算

注:在下表中输入桥架规格、桥架长度、吊杆长度 规格理论重量kg/m长度m规格理论重量kg/m长度m间距m个数重量100kg 505010001.000000.00 10050910.661500.8880.8881.0050*53.770.252455.3312.38 15050695.23200φ120.8881.00l40*42.4220.32347.6158.70 200100532.59300φ120.8881.00l40*42.4220.352266.2956.99 30010086.89400φ120.8881.00l40*42.4220.45243.4451.25 30020050001.000000.00 40010054.

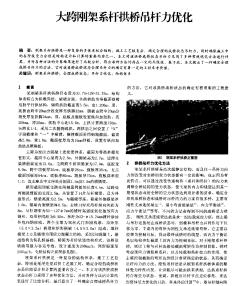

吊杆编号计算销铰中心长度(m)设计销铰中心长度(m)计算和设计差值(m) 179.066979.0640.0029 272.915972.8990.0169 367.029467.0020.0274 461.407061.3690.0380 556.048056.0020.0460 650.951950.8980.0539 746.158346.0980.0603 841.586341.5210.0653 937.275337.2060.0693 1033.225033.1530.0720 1129.435129.3620.0731 1225.935125.8620.0731 1322.674922.6000.0749 1419.684219.6100.0742 1516.962916.893

目前,一般矿山井下电机车运输都使用“张拉法”架设电机车的电源线。用这种方法架线,不仅要消耗大量的铁丝和钢钎,而且拉线的铁丝要横跨整个巷道,给行人和运输带来一定的不便。为了解

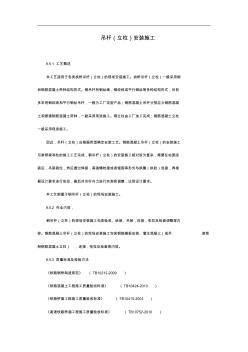

吊杆(立柱)安装施工 9.5.1工艺概述 本工艺适用于各类拱桥吊杆(立柱)的现场安装施工。拱桥吊杆(立柱)一般采用钢 和钢筋混凝土两种结构形式。钢吊杆有钢丝绳,钢绞线或平行钢丝等多种结构形式,目前 多采用钢绞线和平行钢丝吊杆,一般为工厂定型产品;钢筋混凝土吊杆分预应力钢筋混凝 土和普通钢筋混凝土两种,一般采用现浇施工。钢立柱由工厂加工完成;钢筋混凝土立柱 一般采用现浇施工。 因此,吊杆(立柱)应根据类型确定安装工艺。钢筋混凝土吊杆(立柱)的安装施工 可参照梁和柱的施工工艺完成,钢吊杆(立柱)的安装施工相对较为复杂,需要在地面组 装后,吊装就位,然后通过焊接,高强螺栓接或者锚固等形式与拱圈(拱肋)连接,再根 据设计要求进行张拉,最后对吊杆内力进行实测和调整,达到设计要求。 本工艺侧重于钢吊杆(立柱)的现场安装施工。 9.5.2作业内容, 钢吊杆(立柱)的现场安装施工包含验收、组装、吊装,

天津国泰桥是采用两片平行的钢桁架拱肋结构的拱桥,其主梁采用了焊接箱形端面结构。受桥型的限制,张拉端设置在张拉空间较小的梁端。吊杆索体内预埋光纤光栅,用来检测索体的健康状况。索体内预埋光纤光栅,增加了吊杆的安装难度。简要介绍天津国泰桥吊杆的施工安装过程,为以后拱桥吊杆施工提供一些参考。

大跨刚架系杆拱桥吊杆力优化——刚架系杆拱桥是一种复杂的多体系组合结构,施工工艺较复杂,确定合理的成桥状态吊杆力,同时确保施工中的各阶段受力合理是结构设计和计算的重要内容之一。本文对该拱桥成桥状态吊杆力采用了多种常规优化方法进行计算,并对各种方...

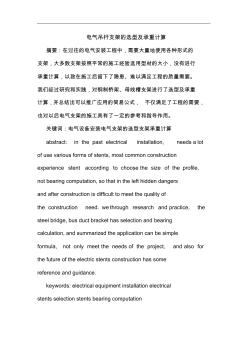

电气吊杆支架的选型及承重计算 摘要:在过往的电气安装工程中,需要大量地使用各种形式的 支架,大多数支架按照平常的施工经验选用型材的大小,没有进行 承重计算,以致在施工后留下了隐患、难以满足工程的质量需要。 我们经过研究和实践,对钢制桥架、母线槽支架进行了选型及承重 计算,并总结出可以推广应用的简易公式,不仅满足了工程的需要, 也对以后电气支架的施工具有了一定的参考和指导作用。 关键词:电气设备安装电气支架的选型支架承重计算 abstract:inthepastelectricalinstallation,needsalot ofusevariousformsofstents,mostcommonconstruction experiencestentaccordingtochoosethesizeoftheprofile, not

文中以广州丫髻沙大桥钢管拱桥吊杆更换的工程实际为背景,分析了拱桥吊杆的病害原因,针对出现的病害,介绍了拱桥新吊杆的改进设计方案。

文辑创建者

我要分享 >

职位:造价审核岗

擅长专业:土建 安装 装饰 市政 园林

相关编辑

文辑推荐

知识推荐

百科推荐