美制UN螺纹尺寸

2025-05-01

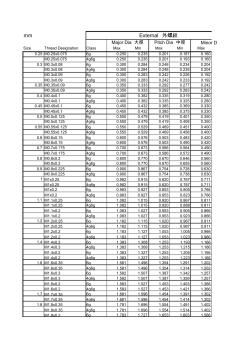

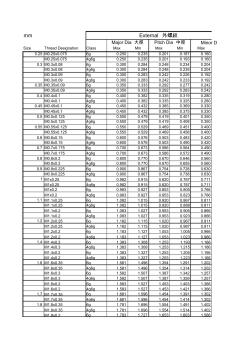

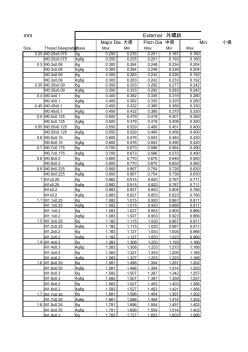

inch External Size 尺寸 Thread Designation 螺 紋規格名稱 Class Max Min Max Min Max 0.0118 30-318 UNM 2A 0.0118 0.0112 0.0098 0.0092 0.0080 0.0138 35-282 UNM 2A 0.0138 0.0131 0.0115 0.0109 0.0095 0.0157 40-254 UNM 2A 0.0157 0.0150 0.0132 0.0126 0.0110 0.0177 45-254 UNM 2A 0.0177 0.0170 0.0152 0.0145 0.0130 0.0197 50-203 UNM 2A 0.0197 0.0189 0.0165 0.0158 0.0138 0.021 0000-160 NS 2A 0.021 0.0195 0.0169 0.01

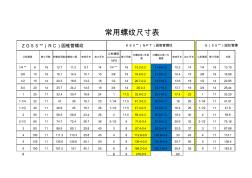

UN_美制螺纹及尺寸表

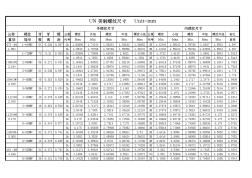

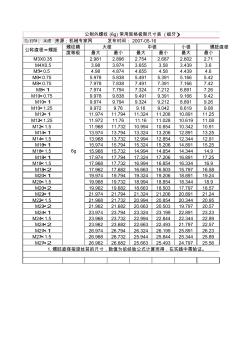

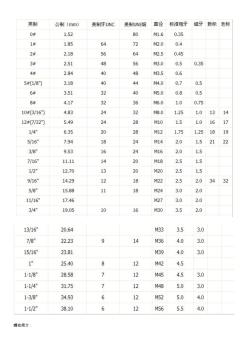

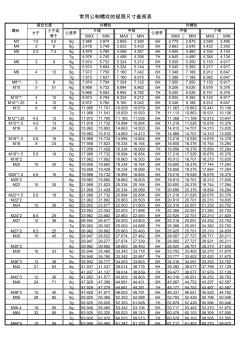

公称螺纹牙牙螺公差螺纹外径螺纹中径螺纹小径公差螺纹小径螺纹中径螺纹外径钻孔 直径规格数高距代号maxminmaxminmax代号minmaxminmaxmin直径 0.073(#1)1-64unc640.2360.3972a1.838961.742441.582421.531621.366522b1.424941.582421.597661.66371.85421.397 1.8543a1.85421.757681.597661.559561.381763b1.424941.582421.597661.645921.85421.397 1-72unf720.210.3532a1.838961.750061.610361.56211.419862

编辑推荐下载

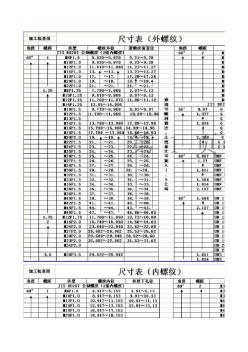

美制螺纹尺寸表 外螺纹 公称螺纹牙牙螺公差螺纹外径螺纹中径螺纹小径公差螺纹 直径规格数高距代号maxminmaxminmax代号min 0.073(#1)1-64unc640.2360.3972a1.838961.742441.582421.531621.366522b1.42494 1.8543a1.85421.757681.597661.559561.381763b1.42494 1-72unf720.210.3532a1.838961.750061.610361.56211.419862b1.4732 3a1.85421.76531.62561.590041.43513b1.4732 0.086(#2)2-56unc560.2710.45

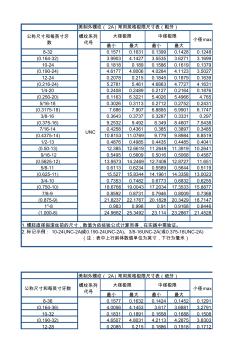

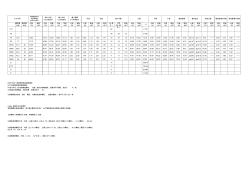

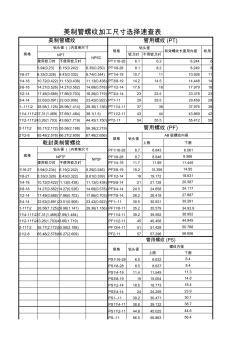

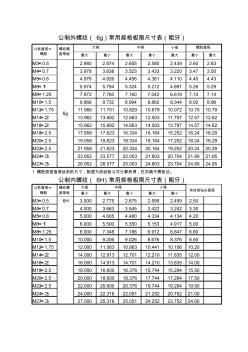

1 美制外螺纹(2a)常用规格极限尺寸表(粗牙) 公称尺寸和 每英寸牙数 螺纹 系列 代号 大径极限中径极限 小径max 螺胚直径 最小最大最小最大最小最大 8-32 unc 0.15710.16310.13990.14280.1248 3.583.61 (0.164-32)3.99034.14273.55353.62713.1699 10-240.18180.18900.15860.16190.1379 4.074.10 (0.190-24)4.61774.80064.02844.11233.5027 12-240.20780.21500.18450.18790.1639 4.724.75 (0.216-24)5.2781

热门文档 美制UN螺纹尺寸

最小最大最小最大 8-320.15710.16310.13990.14280.1248 (0.164-32)3.99034.14273.55353.62713.1699 10-240.18180.1890.15860.16190.1379 (0.190-24)4.61774.80064.02844.11233.5027 12-240.20780.2150.18450.18790.1639 (0.216-24)5.27815.4614.68634.77274.1631 1/4-200.24080.24890.21270.21640.1876 (0.250-20)6.11636.32215.40265.49664.765 5/16-180.30260.31130.27120.27520.2

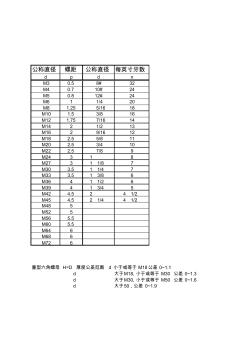

公称直径螺距公称直径每英寸牙数 dpdn m30.58#32 m40.710#24 m50.812#24 m611/420 m81.255/1618 m101.53/816 m121.757/1614 m1421/213 m1629/1612 m182.55/811 m202.53/410 m222.57/89 m24318 m27311/87 m303.511/47 m333.513/86 m36411/26 m39413/45 m424.5241/2 m454.521/441/2 m485 m525 m565.5 m605.5 m646 m686 m726 重型六角螺母h=d厚度公差范围d小于或等于m18公

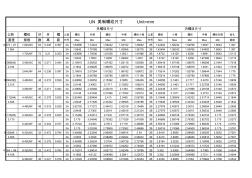

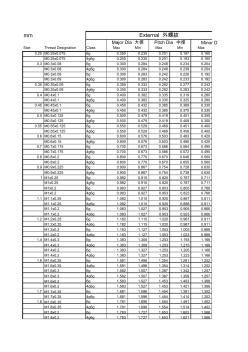

mm sizethreaddesignationclassmaxminmaxminmax 0.25m0.25x0.0756g0.2500.2350.2010.1870.160 m0.25x0.0754g6g0.2500.2350.2010.1930.160 0.3m0.3x0.086g0.3000.2840.2480.2340.204 m0.3x0.084g6g0.3000.2840.2480.2390.204 m0.3x0.096g0.3000.2830.2420.2260.192 m0.3x0.094g6g0.3000.2830.2420.2330.192 0.35m0.35x0.096g0.3500.3330.2920.2770.242 m0.35x0.094g6g0.350

公称直径螺距 dpal2 m330.52.2411481.8 m3.53.5-0.62.5502 m440.73.152.5 m4.54.5-0.753.552.8 m550.8416583.15 m664.5193.55 m775.6194.57 m886.35 m997.15.6 m10102480 m11112585 m12121.75929897.110 m141411.23095912 m161612.5321021013 m1818 m2020 m2222163811812.516 m2424181301418 m2727135 m303048138 m333322.4511511822 m3

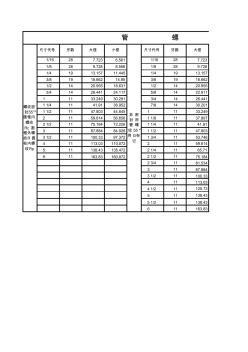

镀锌管 外经 塑料管 外经 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt g(直 牙) 公制 zg(锥 牙) 英制 npt 公制 zg 英制 nptg 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 公制 zg 英制 npt 1/16287.723 1/82828279.728 1/413.513.6213.1613.6212.6613.131.301.430.861.131.341.4119191813.1613.6213.1612.3012.4911.4511.366.005.79φ11.2φ11.19.

精华文档 美制UN螺纹尺寸

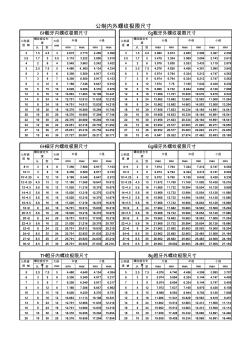

螺纹精小径 度等级最大最小最大最小最大最小 m3x0.352.9812.8962.7542.6872.6022.71 m4x0.53.983.8743.6553.583.4393.6 m5×0.54.984.8744.6554.584.4394.6 m6×0.755.9785.8385.4915.3915.1665.42 m8×0.757.9787.8387.4917.3917.1667.42 m8×17.9747.7947.3247.2126.8917.26 m10×0.759.9789.8389.4919.3919.1669.42 m10×19.9749.7949.3249.2128.8919.26 m10×1.259.9729.769.169.0428.6199.

mm sizethreaddesignationclassmaxminmaxminmax 0.25m0.25x0.0756g0.2500.2350.2010.1870.160 m0.25x0.0754g6g0.2500.2350.2010.1930.160 0.3m0.3x0.086g0.3000.2840.2480.2340.204 m0.3x0.084g6g0.3000.2840.2480.2390.204 m0.3x0.096g0.3000.2830.2420.2260.192 m0.3x0.094g6g0.3000.2830.2420.2330.192 0.35m0.35x0.096g0.3500.3330.2920.2770.242 m0.35x0.094g6g0.350

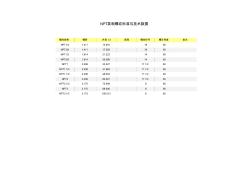

npt英制螺纹标准与技术数据 螺纹规格螺距外径c1底径螺纹标号螺牙角度备注 npt1/41.41113.6161860 npt3/81.41117.0551860 npt1/21.81421.2231460 npt5/81.81426.5681460 npt12.20833.227111/260 npt11/42.20841.984111/260 npt11/22.20848.053111/260 npt22.20860.091111/260 npt21/23.17572.699860 npt33.17588.608860 npt31/23.175100.013860 pt:美国标准的60度锥管螺纹 美制一般密封管螺纹的基本尺寸: 尺寸 代号 牙数

螺纹简介: 1.1螺纹的起源 一般认为,阿基米德(公元前287-212年)是首先将螺纹用于工业目的,即将低处的水移到高处的一种工具。 1659年法国人贝兹逊发明螺纹切割机;其后,经过英国的威阿特、亨利?莫斯列,到其子弟约瑟夫?惠氏于1841年才 统一原本混乱的螺纹,促进螺纹制品的全球普及;因此,惠氏螺纹也随英国工业的发达而广泛传播世界。 美制螺纹依据塞勒氏螺纹(seller'sthread)而问世于1924年;二次世界大战中,美国、英国、加拿大三国协 定发展成统一制螺纹unifiedthread。随着国际交流的频繁,1947年成立的iso国际标准化组织(internationalstandard organization)成为推动国际标准化的重要力量。 1.2螺纹概述 按用途分类,可分为紧固螺纹、密封螺纹、传动螺纹、管螺纹、专用螺纹。 1.3螺纹的分

最新文档 美制UN螺纹尺寸

铰刀时不用铰刀时 使用铰刀时不使用铰刀时pt1\16-286.16.26.2446 .5.94(0.23)6.15(0.242)6.35(0.250)pt1\8-288.18.28.2498 1\8-278.33(0.328)8.43(0.332)8.74(0.344)pt1\4-1910.71110.92611 1\4-1810.72(0.422)11.13(0.438)11.13(0.438)pt3\8-1914.214.514.44814 3\8-1814.27(0.526)14.27(0.562)14.68(0.578)pt1\2-1417.61817.97918 1\2-1417.48(0.688)17.86(0.703)18.26(0.719)pt3\4-142323.523.3782

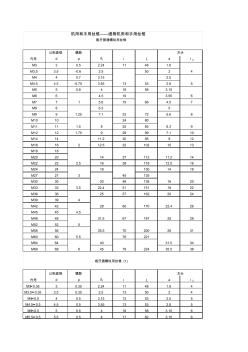

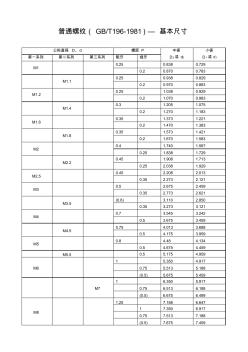

普通螺纹(gb/t196-1981)—基本尺寸 公称直径d、d螺距p中径 d2或d2 小径 d1或d1第一系列第二系列第三系列粗牙细牙 m1 0.250.8380.729 0.20.8700.783 m1.1 0.250.9380.829 0.20.9700.883 m1.2 0.251.0380.929 0.21.0700.983 m1.4 0.31.2051.075 0.21.2701.183 m1.6 0.351.3731.221 0.21.4701.383 m1.8 0.351.5731.421 0.21.6701.583 m2 0.41.7401.567 0.251.8381.729 m2.2 0.451.9081.713 0.252.0381.9

大径中径小径牙高大径中径小径牙高 10.2510.8380.7290.135121.751210.86310.1060.947 1.10.251.10.9380.8290.1351421412.70111.8351.083 1.20.251.21.0380.9290.1351621614.70113.8351.083 1.40.31.41.2051.0750.162182.51816.37615.2941.353 1.60.351.61.3731.2210.189202.52018.37617.2941.353 1.80.351.81.5731.4210.189222.52220.37619.2941.353 20.421.741.567

公制外螺纹(6g)常用规格极限尺寸表(粗牙) 小径 最大最小最大最小最大最小最大 m3×0.52.9802.8742.6552.5802.4392.602.63 m4×0.73.9783.8383.5233.4333.2203.473.50 m5×0.84.9764.8264.4564.3614.1104.404.43 m6×15.9745.7945.3245.2124.8915.265.29 m8×1.257.9727.7607.1607.0426.6197.107.14 m10×1.59.9689.7328.9948.8628.3448.928.96 m12×1.7511.96611.70110.82910.67910.07210.7510.79 m14×213.9621

mm sizethreaddesignationclassmaxminmaxminmax 0.25m0.25x0.0756g0.2500.2350.2010.1870.160 m0.25x0.0754g6g0.2500.2350.2010.1930.160 0.3m0.3x0.086g0.3000.2840.2480.2340.204 m0.3x0.084g6g0.3000.2840.2480.2390.204 m0.3x0.096g0.3000.2830.2420.2260.192 m0.3x0.094g6g0.3000.2830.2420.2330.192 0.35m0.35x0.096g0.3500.3330.2920.2770.242 m0.35x0.094g6g0.350

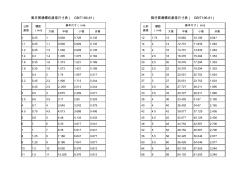

从到minmaxminmax从到maxminmaxminmaxmin 31.54.532.6752.7752.4592.59931.54.52.9802.8742.6552.5802.3672.256 3.51.753.53.1103.2222.8503.0103.51.753.4793.3543.0893.0042.7432.615 42643.5453.6633.2423.4224263.9783.8383.5233.4333.1192.979 52.57.554.4804..6054.1344.33452.57.54.9764.8264.4564.3613.9953.842 63965.3505.5004.9175.1

mm sizethreaddesignationclassmaxminmaxminmax 0.25m0.25x0.0756g0.2500.2350.2010.1870.160 m0.25x0.0754g6g0.2500.2350.2010.1930.160 0.3m0.3x0.086g0.3000.2840.2480.2340.204 m0.3x0.084g6g0.3000.2840.2480.2390.204 m0.3x0.096g0.3000.2830.2420.2260.192 m0.3x0.094g6g0.3000.2830.2420.2330.192 0.35m0.35x0.096g0.3500.3330.2920.2770.242 m0.35x0.094g6g0.350

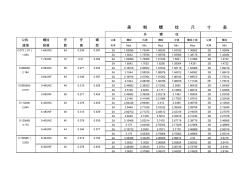

公称通径 nps 1/4″81912.711.29.7141/4″1813.2-0.211.4+0.210.2141/41913.15 3/8101916.114.510.1153/81816.6-0.214.8+0.210.4153/81916.66 1/2151420.318.813.2181/21420.7-0.218.5+0.213.6181/21420.95 3/4201425.724.214.5193/41426-0.323.7+0.213.7193/41426.44 1251132.430.416.824111.532.6-0.329.7+0.217.42311133.25 1-1/43211413919.125

maxminmaxminmaxminmaxmin m31.54.56g2.9802.8742.6552.5806h2.7752.6752.5902.495 m4266g3.4783.7493.5233.4336h3.6633.5453.4223.242 m52.57.56g4.9794.7604.4564.3616h4.6054.4804.3344.134 7g4.9764.7404.4564.3067h4.6404.4804.3844.134 m6396g5.9745.7325.3245.2126h5.5005.3505.1534.917 7g5.9745.6945.3245.1447h5.5405.3505.2174.917 m8412

1/16287.7236.5611/16287.723 1/8289.7288.5661/8289.728 1/41913.15711.4451/41913.157 3/81916.66214.953/81916.662 1/21420.95518.6311/21420.955 3/41426.44124.1175/81422.911 11133.24930.2913/41426.441 11/41141.9138.9527/81430.201 11/21147.80344.84511133.249 21159.61456.65611/81137.897 21/21175.18472.22611/41141.91 31187.88484.926

文辑创建者

我要分享 >

职位:全过程工程咨询工程师

擅长专业:土建 安装 装饰 市政 园林

相关编辑

文辑推荐

知识推荐

百科推荐