弯头三通大小头理论重量表

2025-04-16

弯头三通大小头理论重量表

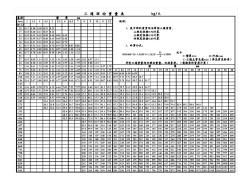

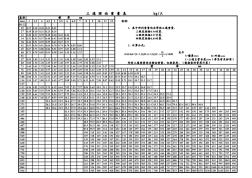

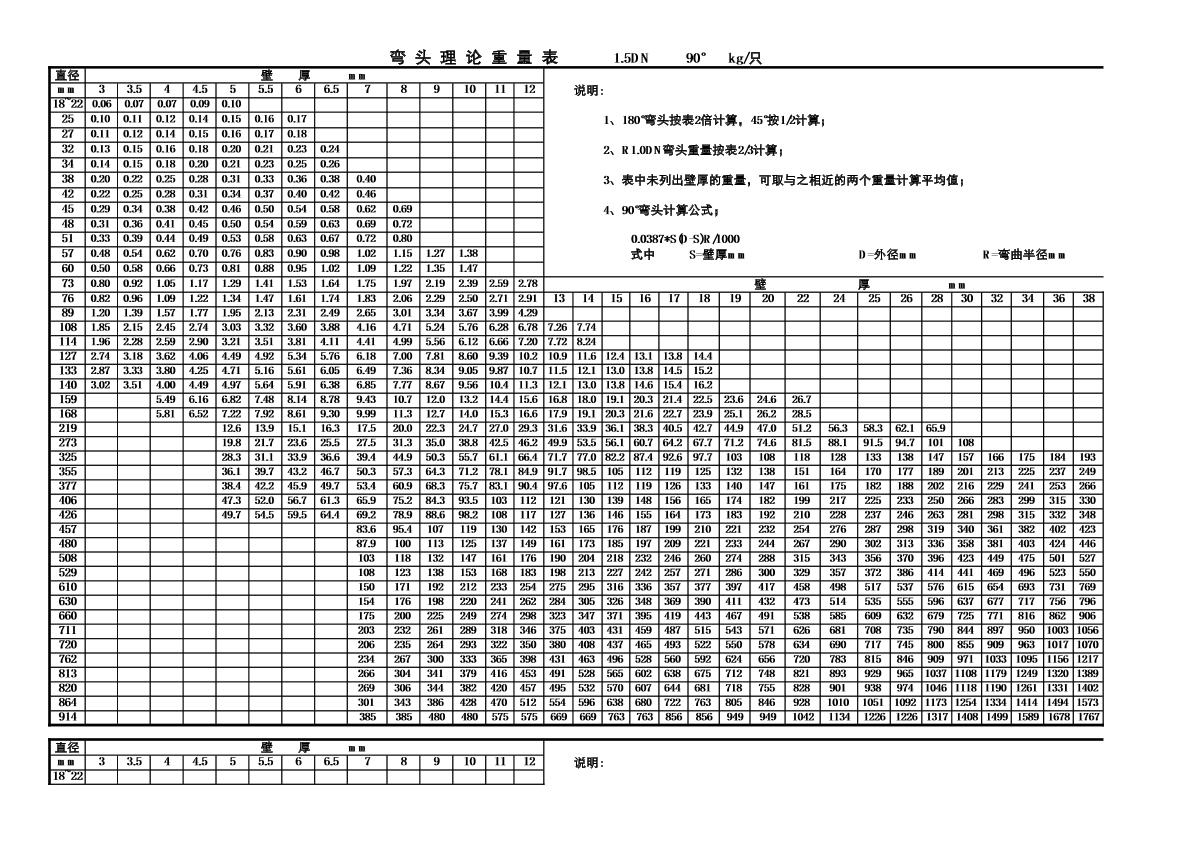

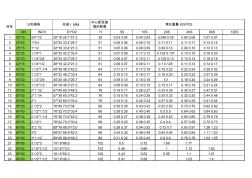

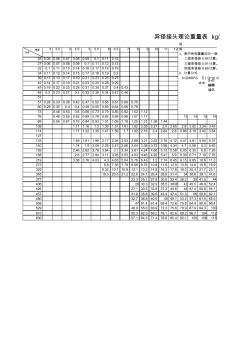

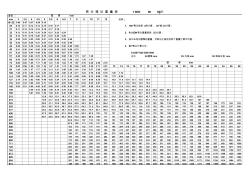

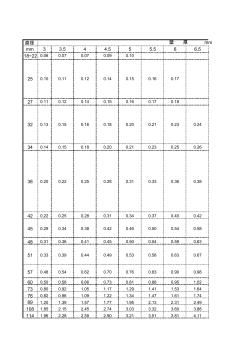

直径 mm33.544.555.566.5789101112说明: 18~220.060.070.070.090.10 250.100.110.120.140.150.160.171、180°弯头按表2倍计算,45°按1/2计算; 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.242、r1.0dn弯头重量按表2/3计算; 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.380.403、表中未列出壁厚的重量,可取与之相近的两个重量计算平均值; 420.220.250.280.310.340

编辑推荐下载

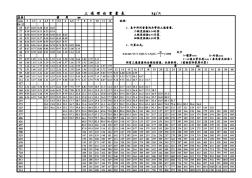

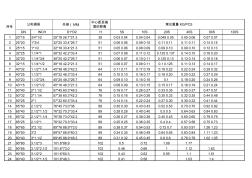

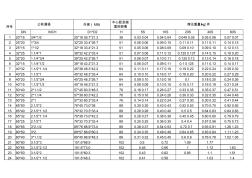

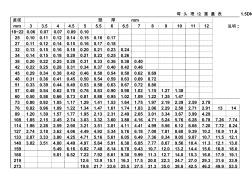

外径(mm)中心距至端 面的距离 dninchd1*d2h5s10s20s40s80s120s 120*153/4*1/225*1826.7*21.3380.030.040.040.040.0490.050.050.060.070.07 225*201*3/432*2533.4*26.7510.060.060.090.100.110.110.110.110.140.15 325*151*1/232*1833.4*21.3510.050.060.080.090.090.100.090.100.120.13 432*251.1/4*138*3242.2*33.4510.070.080.110.120.1250.1370.140.150.180.20 53

热门文档 弯头三通大小头理论重量表

外径(mm)中心距至端 面的距离 dninchd1*d2h5s10s20s40s80s120s 120*153/4*1/225*1826.7*21.3380.030.040.040.040.0490.050.050.060.070.07 225*201*3/432*2533.4*26.7510.060.060.090.100.110.110.110.110.140.15 325*151*1/232*1833.4*21.3510.050.060.080.090.090.100.090.100.120.13 432*251.1/4*138*3242.2*33.4510.070.080.110.120.1250.1370.140.150.180.20 53

外径(mm)中心距至端 面的距离 dninchd1*d2h5s10s20s40s80s120s 120*153/4*1/225*1826.7*21.3380.030.040.040.040.0490.050.050.060.070.07 225*201*3/432*2533.4*26.7510.060.060.090.100.110.110.110.110.140.15 325*151*1/232*1833.4*21.3510.050.060.080.090.090.100.090.100.120.13 432*251.1/4*138*3242.2*33.4510.070.080.110.120.1250.1370.140.150.180.20 53

外径(mm)中心距至端 面的距离 dninchd1*d2h5s10s20s40s80s 120*153/4*1/225*1826.7*21.3380.030.040.040.040.0490.050.050.060.070.07 225*201*3/432*2533.4*26.7510.060.060.090.100.110.110.110.110.140.15 325*151*1/232*1833.4*21.3510.050.060.080.090.090.100.090.100.120.13 432*251.1/4*138*3242.2*33.4510.070.080.110.120.1250.1370.140.150.180.20 532*20

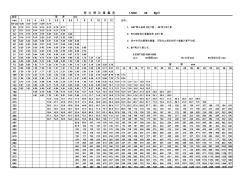

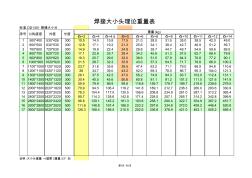

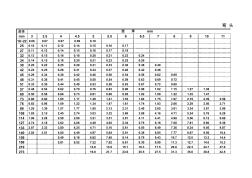

33.544.555.566.5789101112 说 明: 250.050.060.070.080.090.10.110.12 270.060.070.080.090.10.110.120.13 320.10.110.130.140.160.170.180.19 340.110.120.140.150.170.180.190.2 390.130.130.170.190.210.230.250.27 420.140.170.190.210.230.250.280.29式中 s=大 端壁 450.190.220.230.280.310.340.370.40.43 d=小 端外 480.20.230.270.30.330.360.340.

精华文档 弯头三通大小头理论重量表

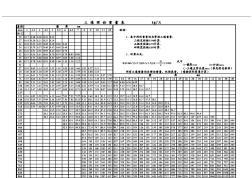

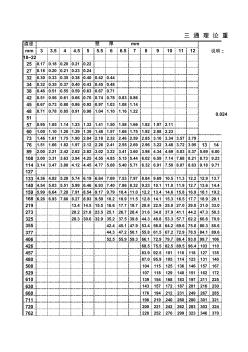

标准:dd1301普通大小头 δ=3δ=4δ=4.5δ=5δ=6δ=8δ=9δ=10δ=11δ=12δ=14 1500*400530*42630010.514.015.817.521.028.031.535.038.542.049.0 2600*500630*53030012.817.119.221.325.634.138.442.746.951.259.7 3700*600720*63030014.919.922.424.829.839.744.749.754.659.669.5 4800*700820*72030017.122.825.728.434.245.651.357.062.768.479.8 5900*800920*82030019.

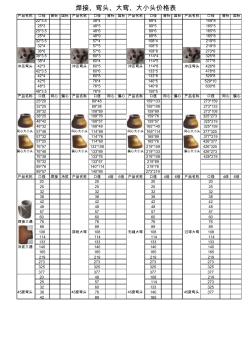

产品名称口径普标国标产品名称口径普标国标产品名称口径普标国标产品名称口径普标国标 22*3.548*489*4159*8 25*348*589*5165*5 25*3.548*689*6165*6 25*448*989*8165*8 32*3.557*4108*4219*6 32*457*5108*5219*8 36*657*6108*8273*8 38*3.560*3114*4325*8 38*460*4114*5377*8 冲压弯头42*3冲压弯头60*5冲压弯头114*8冲压弯头426*8 42*3.560*6133*5478*8 42*460*8133*8529*8 42*576*4140*5529*10 48*376*5140*8630*8 48*3.576

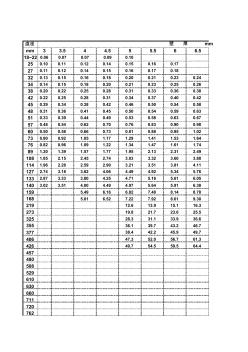

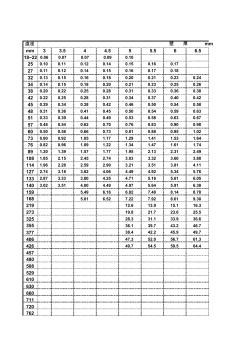

直径 mm33.544.555.566.5 18~220.060.070.070.090.10 250.100.110.120.140.150.160.17 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.24 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.38 420.220.250.280.310.340.370.400.42 450.290.340.380.420.460.500.540.58 480.310.360.410.450.500.540.590.63 510.

最新文档 弯头三通大小头理论重量表

直径 mm33.544.555.566.5789101112说明: 18~220.060.070.070.090.10 250.100.110.120.140.150.160.171、180°弯头按表2倍计算,45°按1/2计算; 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.242、r1.0dn弯头重量按表2/3计算; 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.380.403、表中未列出壁厚的重量,可取与之相近的两个重量计算平均值; 420.220.250.280.310.340

直径 mm33.544.555.566.5 18~220.060.070.070.090.10 250.100.110.120.140.150.160.17 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.24 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.38 420.220.250.280.310.340.370.400.42 450.290.340.380.420.460.500.540.58 480.310.360.410.450.500.540.590.63 510.

直径 mm33.544.555.566.5 18~220.060.070.070.090.10 250.100.110.120.140.150.160.17 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.24 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.38 420.220.250.280.310.340.370.400.42 450.290.340.380.420.460.500.540.58 480.310.360.410.450.500.540.590.63 510.

直径 mm33.544.555.566.5789101112说明: 18~220.060.070.070.090.10 250.100.110.120.140.150.160.17 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.24 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.380.40 420.220.250.280.310.340.370.400.420.46 450.290.340.380.420.460.500.540.580.620.69 480.310

直径 mm33.544.555.566.57891011 18~220.060.070.070.090.10 250.100.110.120.140.150.160.17 270.110.120.140.150.160.170.18 320.130.150.160.180.200.210.230.24 340.140.150.180.200.210.230.250.26 380.200.220.250.280.310.330.360.380.40 420.220.250.280.310.340.370.400.420.46 450.290.340.380.420.460.500.540.580.620.69 480.310.360.4

通风工程设计预算及施工用料计量时,对于变径弯头及大小头等部件的表面积,是按规定的数学计算式计算的。计算过程繁琐复杂。为了解决这一问题,现介绍一种通风管件中变径圆弯头及圆大小头的表面积速算式:1.变径圓弯头表面积速算式的推导

直径 mm33.544.555.566.5789101112说明: 18~22 250.170.180.200.210.22 270.180.200.210.230.24 320.300.330.350.380.400.420.44 340.320.350.370.400.430.450.48 380.460.510.550.590.630.670.71 420.510.560.610.660.700.740.780.830.86 450.670.730.800.860.920.971.031.081.14 480.710.780.850.910.981.041.101.161.22 51 570.951.051.141.231.32

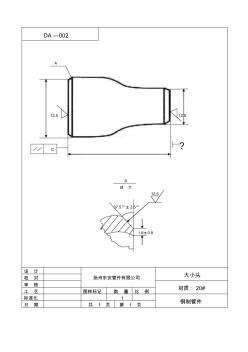

偏心变径的作用 偏心大小头两端管口直径不同,用于连接不同直径的管子或法兰进行变径。偏心大小头的两端 管口,圆心在同一轴线上,变径的时候,以轴线计算管子位置的话,管子的位置不变,一般用 于气体或垂直的液体管道变径。 偏心大小头两端管口圆周内切,一般用于水平的液体管道。偏心大小头的管口切点向上的时候, 称为顶平安装,一般用于泵入口,利于排气 ,切点向下成为底平安装,一般用于调节阀的安装,利用排净。偏心大小头有利于流体流动, 在变径的时候对流体流态的干扰较小,因此气体和垂直流动的液体管道使用同心异径管变径。 偏心大小头由于一侧是平的,利于排气或者排液,方便开车和检修,因此水平安装的液体管道 一般用偏心异径管。 底平flatonbottom(fob) 顶平flatontop(fot) 大小头只有同心和偏心之分,顶平和底平只是偏心大小头的一种安装方法。 所以应该说偏心大小

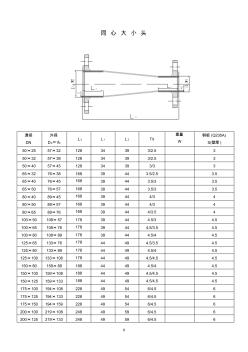

6 同心大小头 ×× 通径 dn 外径 d0×d0 l3l1l2t/t 重量 w 钢板(q235a) s(壁厚) 50×2557×3212834393/2.53 50×3257×3812834393/2.53 50×4057×4512834393/33 65×3276×3816839443.5/2.53.5 65×4076×4516839443.5/33.5 65×5076×5716839443.5/33.5 80×4089×4516839444/34 80×5089×5716839444/34 80×6589×7616839444/3.54 100×50108×5717839444.5/34.5 100×6510

文辑创建者

我要分享 >

职位:建造师课程讲师

擅长专业:土建 安装 装饰 市政 园林

相关编辑

文辑推荐

知识推荐

百科推荐